1. Leading product structure and function design, compact structure, original filter shell overall forming, processing technology, avoid all kinds of leakage caused by steel filter shell welding; 2. High strength ductile iron material excellent anti-corrosion performance, prolong the service life of the product; 3. Proprietary filter element design and manufacturing technology, high precision filter element never wear, pressure inspection never deformation, factory accuracy test to meet user requirements; 4. The coarse and fine screen are made of stainless steel welding mesh, screen plate and screen composed of inside and outside double-layer structure; Because of the active cleaning of the filter element, thus enhancing its anti-interference ability, cleaning thoroughly, especially suitable for poor water conditions. *Compared with the traditional filter has the following characteristics: high degree of automation; Low pressure loss; No manual removal of filter slag is necessary.The automatic cleaning filter is widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, papermaking, food, sugar, pharmaceutical, plastics, automotive industry and other fields.Can be designed according to user requirements, the production of various pressure range of filters; After special process to produce the temperature of more than 95C filter, for the need to work in cold conditions, will use a special filter control system; For the characteristics of seawater corrosion, special materials such as nickel and titanium alloy are selected, and special processing of the filter is carried out. We can provide targeted solutions according to the specific working conditions and requirements of users . The following factors should be considerred when selecting the model of automatic cleaning filter: 1. Treated water quantity; 2. Pipeline pressure of the system; 3. Filtering accuracy required by users; 4. Concentration of suspended matter in filtered impurities; 5. Related physical and chemical properties of filter media.Installation requirements 1. Filter specifications should be selected to match the installation pipeline, when the filter flow cannot meet the requirements of the pipeline, two (or more) filters can be installed in parallel, or do side filter processing. 2. The filter should be installed in the place to protect the system as far as possible. The low pressure at the entrance affects the use, so it should also be installed near the pressure source. 3. The filter should be installed in series in the pipeline system. In order to ensure uninterrupted water supply in the system when the system is shut down for maintenance, it is recommended to set bypass in the system. Where backflow is likely, check valves should be installed at filter outlets. 4. Pay attention to the selection of automatic self-cleaning filter through the water temperature does not exceed its suitable temperature. 5. Three-phase 380V AC power (three-phase four-wire system) is provided at the installation site. Blowdown pipe should not exceed 5 meters to avoid back pressure. 6. Pay attention to filtration accuracy, pretreatment and pressure matters in DC system, and carefully use timing control type in intermittent system. 7. Choose a proper installation environment and ensure that the installation environment is waterproof, rain-proof and moisture-proof. 8. Valves shall be installed at the water inlet, water outlet and sewage discharge outlet of the equipment (the blowdown valve shall be quick valve). 9. The net distance between the devices shall not be less than 1500mm; The net distance between the equipment and the wall is not less than 1000mm; No less than 500mm maintenance space should be left for the equipment and surrounding areas. 10. On the import and export pipe of the equipment, the pipe support shall be set near the pipe mouth; Support shall be provided under valves greater than or equal to DN150 directly connected to the container orifice.1. The self-cleaning filter can only be used according to the rated voltage/frequency marked on the nameplate. 2. Maintain the filter every once in a while. Before cleaning and maintenance, be sure to disconnect the power supply of the self-cleaning filter. 3. Please make sure that the wire plug is not wet during cleaning or it must be dried before reconnecting the power supply. 4. Do not unplug the power cable with wet hands. 5. Self-cleaning filter is only used in indoor aquariums. 6. Do not use the filter if it is damaged, especially the power cable. 7. Please ensure that the self-cleaning filter is working at the correct water level. The filter cannot be used without water. 8. Please do not disassemble or repair it privately to avoid danger or damage to the body. Maintenance should be carried out by professionals

1. Leading product structure and function design, compact structure, original filter shell overall forming, processing technology, avoid all kinds of leakage caused by steel filter shell welding; 2. High strength ductile iron material excellent anti-corrosion performance, prolong the service life of the product; 3. Proprietary filter element design and manufacturing technology, high precision filter element never wear, pressure inspection never deformation, factory accuracy test to meet user requirements; 4. The coarse and fine screen are made of stainless steel welding mesh, screen plate and screen composed of inside and outside double-layer structure; Because of the active cleaning of the filter element, thus enhancing its anti-interference ability, cleaning thoroughly, especially suitable for poor water conditions. *Compared with the traditional filter has the following characteristics: high degree of automation; Low pressure loss; No manual removal of filter slag is necessary.The automatic cleaning filter is widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, papermaking, food, sugar, pharmaceutical, plastics, automotive industry and other fields.Can be designed according to user requirements, the production of various pressure range of filters; After special process to produce the temperature of more than 95C filter, for the need to work in cold conditions, will use a special filter control system; For the characteristics of seawater corrosion, special materials such as nickel and titanium alloy are selected, and special processing of the filter is carried out. We can provide targeted solutions according to the specific working conditions and requirements of users . The following factors should be considerred when selecting the model of automatic cleaning filter: 1. Treated water quantity; 2. Pipeline pressure of the system; 3. Filtering accuracy required by users; 4. Concentration of suspended matter in filtered impurities; 5. Related physical and chemical properties of filter media.Installation requirements 1. Filter specifications should be selected to match the installation pipeline, when the filter flow cannot meet the requirements of the pipeline, two (or more) filters can be installed in parallel, or do side filter processing. 2. The filter should be installed in the place to protect the system as far as possible. The low pressure at the entrance affects the use, so it should also be installed near the pressure source. 3. The filter should be installed in series in the pipeline system. In order to ensure uninterrupted water supply in the system when the system is shut down for maintenance, it is recommended to set bypass in the system. Where backflow is likely, check valves should be installed at filter outlets. 4. Pay attention to the selection of automatic self-cleaning filter through the water temperature does not exceed its suitable temperature. 5. Three-phase 380V AC power (three-phase four-wire system) is provided at the installation site. Blowdown pipe should not exceed 5 meters to avoid back pressure. 6. Pay attention to filtration accuracy, pretreatment and pressure matters in DC system, and carefully use timing control type in intermittent system. 7. Choose a proper installation environment and ensure that the installation environment is waterproof, rain-proof and moisture-proof. 8. Valves shall be installed at the water inlet, water outlet and sewage discharge outlet of the equipment (the blowdown valve shall be quick valve). 9. The net distance between the devices shall not be less than 1500mm; The net distance between the equipment and the wall is not less than 1000mm; No less than 500mm maintenance space should be left for the equipment and surrounding areas. 10. On the import and export pipe of the equipment, the pipe support shall be set near the pipe mouth; Support shall be provided under valves greater than or equal to DN150 directly connected to the container orifice.1. The self-cleaning filter can only be used according to the rated voltage/frequency marked on the nameplate. 2. Maintain the filter every once in a while. Before cleaning and maintenance, be sure to disconnect the power supply of the self-cleaning filter. 3. Please make sure that the wire plug is not wet during cleaning or it must be dried before reconnecting the power supply. 4. Do not unplug the power cable with wet hands. 5. Self-cleaning filter is only used in indoor aquariums. 6. Do not use the filter if it is damaged, especially the power cable. 7. Please ensure that the self-cleaning filter is working at the correct water level. The filter cannot be used without water. 8. Please do not disassemble or repair it privately to avoid danger or damage to the body. Maintenance should be carried out by professionalsSelf-Cleaning Water Treatment Filter

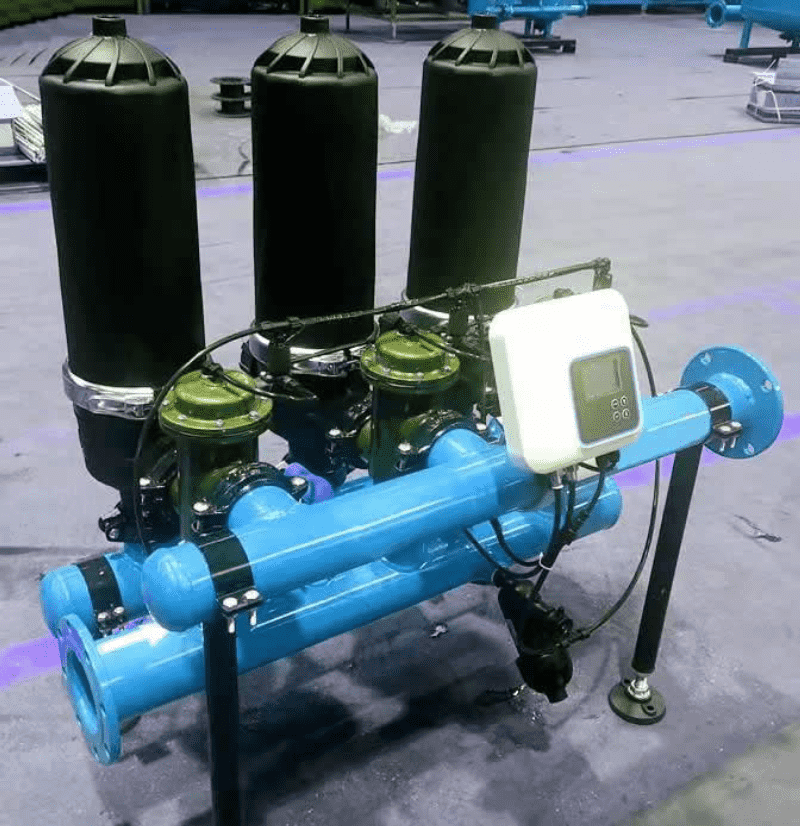

Shop our high-quality self-cleaning water treatment filter. As a factory, we offer efficient filtration solutions to ensure clean water for your needs.

Request a QuotePRODUCTS DETAILS

1. Leading product structure and function design, compact structure, original filter shell overall forming, processing technology, avoid all kinds of leakage caused by steel filter shell welding; 2. High strength ductile iron material excellent anti-corrosion performance, prolong the service life of the product; 3. Proprietary filter element design and manufacturing technology, high precision filter element never wear, pressure inspection never deformation, factory accuracy test to meet user requirements; 4. The coarse and fine screen are made of stainless steel welding mesh, screen plate and screen composed of inside and outside double-layer structure; Because of the active cleaning of the filter element, thus enhancing its anti-interference ability, cleaning thoroughly, especially suitable for poor water conditions. *Compared with the traditional filter has the following characteristics: high degree of automation; Low pressure loss; No manual removal of filter slag is necessary.The automatic cleaning filter is widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, papermaking, food, sugar, pharmaceutical, plastics, automotive industry and other fields.Can be designed according to user requirements, the production of various pressure range of filters; After special process to produce the temperature of more than 95C filter, for the need to work in cold conditions, will use a special filter control system; For the characteristics of seawater corrosion, special materials such as nickel and titanium alloy are selected, and special processing of the filter is carried out. We can provide targeted solutions according to the specific working conditions and requirements of users . The following factors should be considerred when selecting the model of automatic cleaning filter: 1. Treated water quantity; 2. Pipeline pressure of the system; 3. Filtering accuracy required by users; 4. Concentration of suspended matter in filtered impurities; 5. Related physical and chemical properties of filter media.Installation requirements 1. Filter specifications should be selected to match the installation pipeline, when the filter flow cannot meet the requirements of the pipeline, two (or more) filters can be installed in parallel, or do side filter processing. 2. The filter should be installed in the place to protect the system as far as possible. The low pressure at the entrance affects the use, so it should also be installed near the pressure source. 3. The filter should be installed in series in the pipeline system. In order to ensure uninterrupted water supply in the system when the system is shut down for maintenance, it is recommended to set bypass in the system. Where backflow is likely, check valves should be installed at filter outlets. 4. Pay attention to the selection of automatic self-cleaning filter through the water temperature does not exceed its suitable temperature. 5. Three-phase 380V AC power (three-phase four-wire system) is provided at the installation site. Blowdown pipe should not exceed 5 meters to avoid back pressure. 6. Pay attention to filtration accuracy, pretreatment and pressure matters in DC system, and carefully use timing control type in intermittent system. 7. Choose a proper installation environment and ensure that the installation environment is waterproof, rain-proof and moisture-proof. 8. Valves shall be installed at the water inlet, water outlet and sewage discharge outlet of the equipment (the blowdown valve shall be quick valve). 9. The net distance between the devices shall not be less than 1500mm; The net distance between the equipment and the wall is not less than 1000mm; No less than 500mm maintenance space should be left for the equipment and surrounding areas. 10. On the import and export pipe of the equipment, the pipe support shall be set near the pipe mouth; Support shall be provided under valves greater than or equal to DN150 directly connected to the container orifice.1. The self-cleaning filter can only be used according to the rated voltage/frequency marked on the nameplate. 2. Maintain the filter every once in a while. Before cleaning and maintenance, be sure to disconnect the power supply of the self-cleaning filter. 3. Please make sure that the wire plug is not wet during cleaning or it must be dried before reconnecting the power supply. 4. Do not unplug the power cable with wet hands. 5. Self-cleaning filter is only used in indoor aquariums. 6. Do not use the filter if it is damaged, especially the power cable. 7. Please ensure that the self-cleaning filter is working at the correct water level. The filter cannot be used without water. 8. Please do not disassemble or repair it privately to avoid danger or damage to the body. Maintenance should be carried out by professionals

1. Leading product structure and function design, compact structure, original filter shell overall forming, processing technology, avoid all kinds of leakage caused by steel filter shell welding; 2. High strength ductile iron material excellent anti-corrosion performance, prolong the service life of the product; 3. Proprietary filter element design and manufacturing technology, high precision filter element never wear, pressure inspection never deformation, factory accuracy test to meet user requirements; 4. The coarse and fine screen are made of stainless steel welding mesh, screen plate and screen composed of inside and outside double-layer structure; Because of the active cleaning of the filter element, thus enhancing its anti-interference ability, cleaning thoroughly, especially suitable for poor water conditions. *Compared with the traditional filter has the following characteristics: high degree of automation; Low pressure loss; No manual removal of filter slag is necessary.The automatic cleaning filter is widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, papermaking, food, sugar, pharmaceutical, plastics, automotive industry and other fields.Can be designed according to user requirements, the production of various pressure range of filters; After special process to produce the temperature of more than 95C filter, for the need to work in cold conditions, will use a special filter control system; For the characteristics of seawater corrosion, special materials such as nickel and titanium alloy are selected, and special processing of the filter is carried out. We can provide targeted solutions according to the specific working conditions and requirements of users . The following factors should be considerred when selecting the model of automatic cleaning filter: 1. Treated water quantity; 2. Pipeline pressure of the system; 3. Filtering accuracy required by users; 4. Concentration of suspended matter in filtered impurities; 5. Related physical and chemical properties of filter media.Installation requirements 1. Filter specifications should be selected to match the installation pipeline, when the filter flow cannot meet the requirements of the pipeline, two (or more) filters can be installed in parallel, or do side filter processing. 2. The filter should be installed in the place to protect the system as far as possible. The low pressure at the entrance affects the use, so it should also be installed near the pressure source. 3. The filter should be installed in series in the pipeline system. In order to ensure uninterrupted water supply in the system when the system is shut down for maintenance, it is recommended to set bypass in the system. Where backflow is likely, check valves should be installed at filter outlets. 4. Pay attention to the selection of automatic self-cleaning filter through the water temperature does not exceed its suitable temperature. 5. Three-phase 380V AC power (three-phase four-wire system) is provided at the installation site. Blowdown pipe should not exceed 5 meters to avoid back pressure. 6. Pay attention to filtration accuracy, pretreatment and pressure matters in DC system, and carefully use timing control type in intermittent system. 7. Choose a proper installation environment and ensure that the installation environment is waterproof, rain-proof and moisture-proof. 8. Valves shall be installed at the water inlet, water outlet and sewage discharge outlet of the equipment (the blowdown valve shall be quick valve). 9. The net distance between the devices shall not be less than 1500mm; The net distance between the equipment and the wall is not less than 1000mm; No less than 500mm maintenance space should be left for the equipment and surrounding areas. 10. On the import and export pipe of the equipment, the pipe support shall be set near the pipe mouth; Support shall be provided under valves greater than or equal to DN150 directly connected to the container orifice.1. The self-cleaning filter can only be used according to the rated voltage/frequency marked on the nameplate. 2. Maintain the filter every once in a while. Before cleaning and maintenance, be sure to disconnect the power supply of the self-cleaning filter. 3. Please make sure that the wire plug is not wet during cleaning or it must be dried before reconnecting the power supply. 4. Do not unplug the power cable with wet hands. 5. Self-cleaning filter is only used in indoor aquariums. 6. Do not use the filter if it is damaged, especially the power cable. 7. Please ensure that the self-cleaning filter is working at the correct water level. The filter cannot be used without water. 8. Please do not disassemble or repair it privately to avoid danger or damage to the body. Maintenance should be carried out by professionalsHot Products

Air Flotation Equipment for Water Treatment

Laminated Filter

Multi-stage Softening Water Treatment Equipment

Fiberglass/FRP Pipeline Series

Walnut Shell Filter for Water Treatment

EDI Water Equipment Introduction

Fiberglass Reinforced Plastic/ FRP Fittings Series

Wastewater Treatment Integration Equipment

Inclined Tube Sedimentation Tank

Introduction of Ultrafiltration water treatment equipment

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours