FRP Absorption Tower

FRP Absorption Tower

FRP Chimney

1.FRP Circular Counterflow Cooling Tower :DBNL-CDBNL-GBNL GBNL3 series, FRP Industrial Counterflow Cooling Tower CDBNL3 series , FRP Ultra-low Noise Counterflow Cooling Tower DBNL3 series, FRP Low noise Counterflow cooling Tower The FRP circular cooling tower adopts counterflow gas-heat exchange technology. The main body adopts an all-steel structure with a fiberglass plate enclosure. The FRP tower is equipped with maintenance ladders for normal maintenance of tower equipment. The filler is made of high-quality modified PVC ladder-shaped wavy boards, and the uniform water distribution and enhanced cooling effect are achieved by rotating or tube-type water distribution methods. Reliable operation, durable, easy to assemble:The water collection bucket has a large capacity and is equipped with manual and automatic water supply devices, as well as sewage and overflow pipes, eliminating the need for a separate water tank design:Low cost, light weight, small wind resistance, good stability:The tower body has good stability and strength, and can withstand seismic intensity of level 8 and typhoon attacks of level 12. 2.FRP Square Counter-Flow Cooling Tower : DFNL-GFNL-GFNS series: 1)DFNL series square counter-flow fiberglass cooling tower with low temperature reduction. 2)GFNL series industrial square counter-flow fiberglass cooling tower with medium-high temperature reduction. 3)GFNS series (large) industrial square counter-flow fiberglass cooling tower with medium-high temperature reduction. The square counter-flow fiberglass cooling tower has a water flow rate of 100-4000m³/h per unit. It has the characteristics of good thermal performance, low power consumption, good overall stability, beautiful appearance, low noise, short installation cycle, and low cost. It is widely used in petroleum, chemical, metallurgical, and power generation enterprises.The tower body is a steel frame structure, and the maximum amplitude during operation is less than 0.14mm.The FRP cooling tower adopts a fiberglass material energy recovery type wind tube, and the inner wall curve is an elliptical curve. The pressing process is used for forming, and the outer surface is a smooth resin gel coat layer containing stabilizers. The inner surface is coated with resin twice to maintain a high degree of smoothness and reduce resistance.The reducer is horizontal, low noise, high efficiency, reliably oil-lubricated, and easy to maintain. It also has oil temperature and vibration alarm devices.The motor speed can be controlled manually or automatically through a control cabinet.The PVC filler has good water affinity, oil retention performance, high heat dissipation coefficient, and good temperature resistance performance.The water collector has a drifting water rate of less than 0.01% during high-speed operation, which can be ignored during low-speed operation.Environmentally friendly low-noise, low-speed fan, high inducement soundproof mat, streamlined water collector effectively control the impact of DFN cooling towers on the environment. The tower is beautiful and durable, and its shape is perfectly integrated with the building. The surface layer adopts imported gel coat containing UV absorbers, which is smooth as a mirror and has anti-aging and hard-to-fade properties. The tower body color can be chosen according to user requirements. Maintenance is convenient, and the wall panels are uniquely suspended for installation without bolts, making maintenance easy.A variety of forms are available, including standard, temperature-controlled, ultra-low noise, antifreeze, and industrial cement frame cooling towers to meet different requirements.Special Fan for Cooling Tower

The fiberglass environmental protection tower equipment series includes FRR acid gas purification (absorption) towers, FRP acid mist purification (absorption) towers, FRP exhaust gas absorption towers, FRP scrubbers, FRP esulfurization towers,FRP ion exchange column fiberglass chimneys,FRP bromine towers, FRP compound fertilizer equipment, etc. The customization level is high as the equipment is tailored to meet different customer needs and there are no uniform technical indicators. The following are several common types of tower equipment:

FRP Spray Desulfurization Tower

FRP Bromine tower

FRP Purification Tower

FRP Scrubber Tower

Special Reducer for Cooling Tower

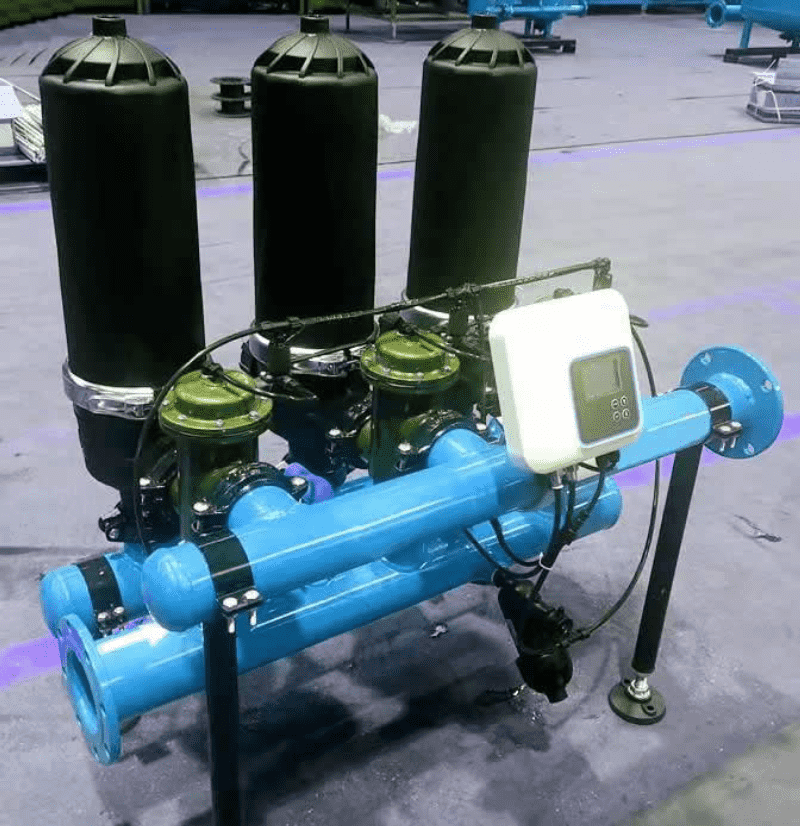

Cooling Tower Sprinkler

Round Cooling Tower Packing

Square Cooling Tower Packing

Cooling Tower Flip Reducer